The increase in prices of certain building materials caught the Hungarian Competition Authority’s interest, and the problem had also been highlighted by the National Federation of Hungarian Building Contractors (ÉVOSZ).

The all-time high, sudden increase in prices, which could even exceed 30 percent by the end of the year according to some forecasts, is causing increasing tensions in the sector.

More and more contractors notice that the cost price of a given project exceeds the price defined in the contract, so they can only carry out the work with loss. In addition to the increase in prices, the shortage of raw materials is giving reasons for concern, which has put the production of certain products at risk. The prices of key raw materials soared to record highs due to the huge demand from emerging economies started to recover at the same time after the pandemic. As a result of previously stopped or restrained production, the warehouses were empty, and parallel to the suddenly growing demand, the raw materials industry would have had to hit the road with full speed and a cold engine.

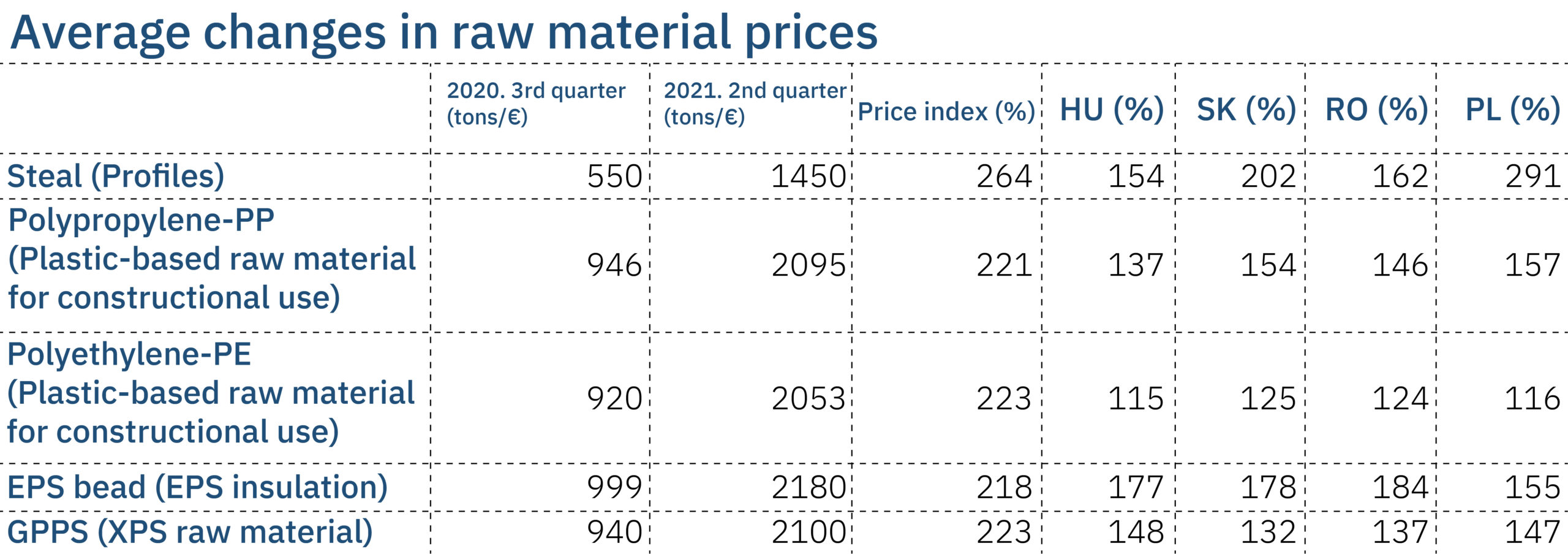

Since last autumn, steel has become almost three times more expensive, and the polypropylene, polyethylene and EPS pearls, which are the raw material for plastic-based construction products, thermal insulation and facade adhesives, have also doubled their prices – said David Tibor, CEO of Department of Hungarian Construction Material Manufacturers of ÉVOSZ and Masterplast Nyrt to Világgazdaság.

He stated that he supports transparency, because it can also help customers to clarify that the vast majority of building material manufacturers have actually raised their prices to the same extent as the price increase of raw materials, therefore, they do not want to take advantage of the increased demand from state subsidies.

The Hungarian Competition Authority’s attention is focused on small-scale, less transparent building material manufacturers in order to detect possible collusion and price cartels.

The Hungarian building materials manufacturer, which operates own subsidiaries in nine countries, found out that in the past six months, the prices of steel and plastic end products in Hungary increased less than in Poland, Slovakia and Romania. Therefore, it is important to note that neither the home renovation supports, nor the state’s efforts to boost demand caused the rise in prices, but rather the rising raw material prices on the world market.

Due to the trends in the building materials market, several large raw material factories have already shut down – usually the biggest international exporting producer German chemical plant and the industrial raw material production suspended due to winter frosts in North America are mentioned as examples, but now some steel mill essential for container production have also stopped, which takes six months to restart. Transport is stalled, and the cost of packaging has also increased due to the price of wood and plastic. Pallets, paper boxes, but even plastic packaging cost more, which basically affects the price of any product.

Change in the market price of the final product in the given period

The increase in the price of materials, which hindrances the total amount of works, is caused by force majeure effects on many sides, therefore the construction department also encourages the possibility of replacement contracts both in the private market and in the case of public procurement. It is not in the interest of the customers to put construction companies in a difficult situation or let them go bankrupt – warns Dávid Tibor.

Meanwhile, the leader of Masterplast does not consider the procurement of raw materials from the East to be a viable option, nor the expansion of the domestic building material production capacity in the short term.

According to the manufacturers, on the other hand, the newly expanded construction strategy is an encouraging sign of the future government intentions. That way, the government aims to increase the volume of domestic production and decrease the dependence on imports, implying that it expects higher demand in the long run. The continuation of the two-year Family Housing Renovation Program and the maintenance of the reduced new housing VAT and other benefits and subsidies can also be good motivations to stimulate the capacity increase – pointed out Tibor Dávid the opportunities inherent in the strategy and the related building materials manufacturers’ hopes.

Masterplast Nyrt.

Founded in 1997, the Masterplast group is one of the leading building material producer and distributor companies in the Central Eastern European region. The company group owns subsidiaries in 10 countries, and sells products in a further 30 countries. The company is registered in the premium category on the Budapest Stock Exchange, and had revenue of 145,2 million euros in 2023.